The ice cream edible cups machine produces delicious edible cups that can be used to hold ice cream and are also edible. This highly practical product revolutionizes the way ice cream and other desserts are served.

It also eliminates traditional plastic or paper waste. The edible cup machine is ideal for ice cream parlors, large dessert manufacturers, and innovative food startups looking to lead the market with sustainable products.

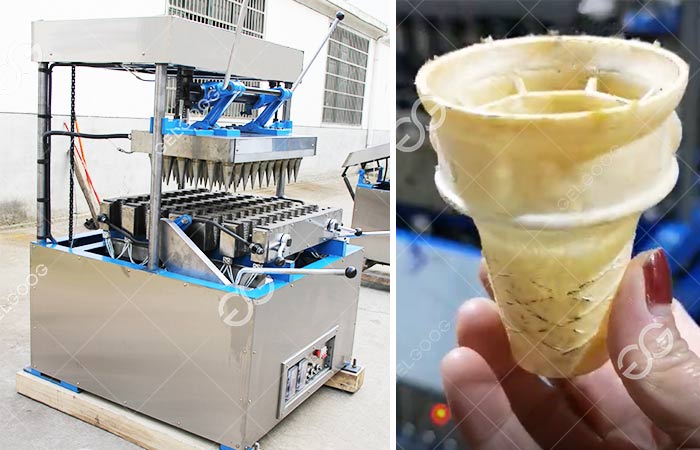

Features of the Ice Cream Edible Cups Machine

- This machine is available in various configurations, with molds ranging from 24 to 60 molds. It can produce 24-60 edible cups at a time, meeting various production capacities.

- Ice cream cups machine features a control panel that displays the temperature and baking time. The baking temperature of the top and bottom heating plates can be precisely set.

- The entire ice cream edible cup production process is semi-automated, with only manual operations required for batter dispensing, pressing the molds, and joining the molds.

- This edible cup making machine accommodates various batter recipes to produce a variety of products, including wafer cups, cones, double-ended cones, and flower-shaped cups.

- It is constructed of food-grade stainless steel and high-quality heating elements. Durable, easy to clean, and meets international food safety standards.

Edible Ice Cream Cups Machine Applications

The primary application of this machine is to create a container that becomes part of the product itself. The cups produced are primarily used to serve ice cream, providing a completely waste-free serving solution.

When the customer finishes the ice cream, they can eat the cup, enhancing the overall fun and novelty of the dessert experience. Beyond ice cream, these sturdy yet edible containers are perfect for holding frozen yogurt, parfaits, mousses, fruit salads, snacks, and even savory dishes like dips or salads, opening up a wide range.

How to Make Ice Cream Edible Cups

- Batter preparation and loading. A beater mixes flour, water, salt, and oil into a uniform, particle-free batter. This batter is then poured into the machine’s storage hopper.

- The temperature and baking time of the upper and lower heating platens are set according to the specific recipe requirements. Initial use can be tested several times to achieve stability.

- A dispenser is used to fill each hopper, and then this precise amount of batter is poured into each mold cavity (ensuring that the lower mold of the edible ice cream cups machine is closed).

- The upper mold is manually pressed down, repeatedly pressing down to squeeze out any air in the cavity. Finally, it is joined with the lower mold, locking the mold.

- Baking occurs according to the set time. When the time is up, a built-in alarm sounds. Then, the mold is opened, and the wafer cups/cones are automatically ejected.

- Prepared trays are collected and manually sorted, stacked, and packaged. If filling materials (nuts, jam, etc.) are required, a filling machine is available.

This professional small to medium sized ice cream edible cups machine is ideal for start-ups. Its affordable price and versatile production capacity make it ideal for businesses looking to expand into this industry or upgrade their equipment.

If you’re unsure about your selection, please leave a message. We’ll contact you and provide step-by-step guidance. We guarantee your satisfaction. Email: [email protected], whatsapp: +8615515571373.

Technical Parameters

| Model | GGDW-60C |

| Capacity(PCS/H) | 1500-2400 |

| Quantity of Moulds | 60PCS |

| Baking time | 1-2 minutes |

| Operation | Semi automatic |

| Power | 21KW |

| Voltage | 380V |

| Machine size(MM) | 1120*1180*1550 |

| Packing size(MM) | 1240*1180*1660 |

| Net Weight | 1046KG |

| Gross weight | 1130KG |

Get a Quote for Your Cone Machine

Let us know your requirements by filling out the form below. our team will get back to you with a tailored quote for the ice cream cone making machine that fits your business.

Reviews

There are no reviews yet.