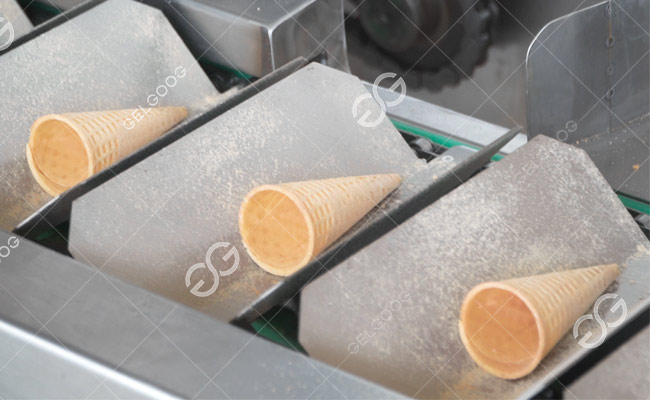

Automatic waffle cone manufacturing machine is a large capacity equipment. This machine integrates quantitative batter delivery, precise molding, high-temperature baking, automatic demoulding and cooling.

It can produce waffle cones and sugar cones in large quantities, with an hourly production capacity of 3000-7500 waffle cones. It meets the large-scale needs of ice cream factories and food companies.

Features of Waffle Cone Processing Machine

- The contact surface material of the machine uses food-grade 304 stainless steel, ensuring excellent corrosion resistance and ease of cleaning.

- This material guarantees both safety and hygiene while maintaining durability for long-term use.

- Uniform and quantitative grouting, automatic opening, grabbing cones, and rolling finished products. The thickness and size of the waffle cones are consistent.

- The baking tray and heating plate of automatic waffle cone manufacturing machine are usually use ductile iron, which not only conducts heat evenly, but also withstands high temperatures and is not easy to deform.

- The machine adopts variable frequency speed control, and workers can adjust it according to actual production needs, greatly improving production efficiency.

- Mixing and filling the batter automatically to the baking plates for baking, and then can adjust amount of slurry according to the size of different waffle cones.

How to Make Waffle Cones?

Advantages of Automatic Waffle Cone Manufacturing Machine

- It can stably produce 1500 to 7500 waffle cones per hour, with a fully automatic process from beating to cone forming. The large production capacity is especially suitable for medium and large ice cream factories.

- The baking plate is made of high temperature resistant material, which allows heat the batter evenly. And the temperature can adjust, so the waffle cones made are golden and crispy, with a very low breakage rate.

- The mold buckle design is particularly fast to change, and after replacement, waffle cones with different patterns or different edges (natural edges and flat edges) can be produced.

- The machine is versatile in design, capable of producing waffle cones, sugar cone, mini cones, egg rolls, and other similar products. Its adaptability makes it suitable for food manufacturers, ranging from medium to large factory.

- The smallest model of the waffle cone processing machine is 6 meters long, 0.8 meters wide, and 1.85 meters high, which is suitable for customers with small factory areas.

After-sales Service and Technical Support

- 24-hour remote fault diagnosis is provided, and spare parts (such as heating tubes and conveyor belt bearings) are stored in the spare parts warehouse all year round.

- Free operator training, guaranteed to teach and learn, with bilingual Chinese and English operation manuals and common problem troubleshooting videos.

Technical Parameters

| Model | Baking plate size(mm) | Voltage | Power | Capacity | Cone length | Size | Weight |

| GG-DCL35×2-18 | 300×320 | 380v 50hz 3phase | 3kw | 1500-2500pcs/h | ≦125mm | 6*0.8*1.85m | 6T |

| GG-DCL37×2-18 | 300×320 | 3kw | 3500-4000pcs/h | ≦125mm | 7*0.8*1.85m | 6T | |

| GG-DCL45×2-18 | 300×320 | 3kw | 4000-4500pcs/h | ≦125mm | 8*0.8*1.85m | 6T | |

| GG-DCL55×2-18 | 300×320 | 3kw | 4500-5500pcs/h | ≦125mm | 9*0.8*1.85m | 7T | |

| GG-DCL65×2-20 | 300×320 | 3kw | 6000-6500pcs/h | ≦125mm | 11*0.8*1.85m | 7T | |

| GG-DCL75×2-22 | 300×320 | 3kw | 6500-7500pcs/h | ≦125mm | 11*1.9*1.85m | 8T |

Get a Quote for Your Cone Machine

Let us know your requirements by filling out the form below. our team will get back to you with a tailored quote for the machine that fits your business.

Click to rate this post!

[Total: 1 Average: 5]

Reviews

There are no reviews yet.