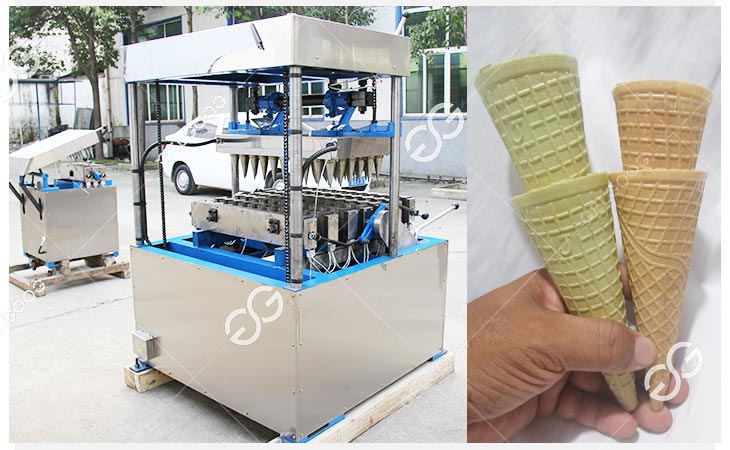

The wafer cone maker machine is a versatile and efficient solution for producing wafer cones. It can create uniform cones and offers adjustable settings to meet specific requirements.

It is ideal for medium-sized to large-sized operations, this machine produces up to 2400 wafer cones per hour, enhancing productivity while maintaining quality.

Characteristic of Wafer Cone Maker Machine

- Mixing System: The machine ensures the perfect batter texture by mixing flour, sugar, and water into a smooth blend.

- Feeding System: A movable hopper dips into the batter, fills precisely, and aligns with the mold aperture for accurate feeding.

- Molding and Baking: High-temperature resistant molds made from quality materials provide even heat distribution, ensuring perfectly baked cones every time.

- Cooling and Unloading: After 1-2 minutes, an alert sounds; the upper mold is manually lifted, the lower mold opens, and the cone falls automatically.

- Compact Design: The machine features a compact footprint, suitable for various environments, with sturdy construction for durability and easy maintenance.

Operation of Industrial Wafer Cone Maker

- Preparation: Ensure the machine is properly installed and connected to power. Prepare the wafer batter according to your recipe.

- Setting Parameters: Use the touchscreen interface to set the desired temperature, baking time, and production speed.

- Starting Production: Once all settings are confirmed, start the industrial wafer cone maker. When the worker put the wafer cone batter into the molds, which will then bake the wafer cones.

- Cooling and Inspection: After baking, the wafer cones fall to the outlet of the machine. After cooling, the cones are manually unloaded and checked for quality. Any defective cones should be discarded.

Customer Feedback

Customers who have invested in the semi-automatic wafer cone maker machine have reported significant improvements in their production processes. Here are some testimonials:

- “Efficiency Boost”: “Since installing this machine, our production efficiency has increased by 50%. We now produce higher quality cones faster than ever before.” – Sarah M., Confectionery Owner

- “Consistent Quality”: “We’ve noticed a marked improvement in the consistency of our cones. The ability to adjust settings ensures we always get the perfect result.” – Emily R., Pastry Chef

- “Space-Saving Design”: “Despite its powerful capabilities, the machine fits perfectly in our limited space. It’s a great balance of functionality and compactness.” – John D., Small Business Owner

By choosing this wafer cone maker machine, you can easily get started, improve product quality and efficiency, and stay competitive in the market. Please send message to email: [email protected] for machine price and details, then increase your ice cream production scale.

Technical Parameters

| Model | GGDW-60C |

| Capacity(PCS/H) | 1500-2400 |

| Quantity of Moulds | 60PCS |

| Baking time | 1-2 minutes |

| Operation | Semi automatic |

| Power | 21KW |

| Voltage | 380V |

| Machine size(MM) | 1120*1180*1550 |

| Packing size(MM) | 1240*1180*1660 |

| Net Weight | 1046KG |

| Gross weight | 1130KG |

Get a Quote for Your Cone Machine

Let us know your requirements by filling out the form below. our team will get back to you with a tailored quote for the machine that fits your business.

Reviews

There are no reviews yet.