What is the manufacturing process of ice cream cones? It involves several key steps, from mixing, baking, rolling, and cooling the ice cream cones. This process ensures automated operation and high efficiency.

Ice cream cones are a beloved companion to frozen treats, but few know how these crispy cones are mass-produced. In this blog, we’ll explore the manufacturing process of ice cream cones in industrial settings.

1. Ingredient Preparation & Mixing

The process begins with raw materials: flour, sugar, water, oil, leavening agents, optional additives. These ingredients are weighed and loaded into automated mixing systems to ensure mixing well.

2. Baking the Sheet

The pump dispenses a precise amount of batter onto the heated baking sheet, the lid is closed and the pan is baked at 180–220°C for 1-2 minutes to create a crispy golden crust.

3. Rolling into Ice Cream Cones

A robotic device moves the baked sheet to the rolling head, where it is formed into uniformly sized ice cream cones in a few seconds. The size of the rolling head can be customized.

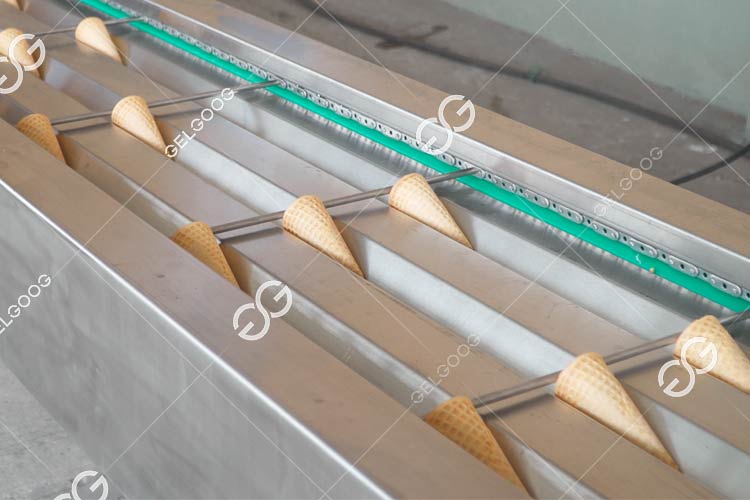

4. Cooling & Hardening

Freshly baked cones are soft and easily deformed. The cooling conveyor cools the ice cream cones to room temperature and arranges them neatly.

5. Quality Inspection

The automated system scans the cones for defects, detecting cracks, uneven thickness or discoloration, and whether there is metal inside the cones. These cones are rejected.

6. Packaging

To preserve freshness and prevent breakage, ice cream cones are placed in paper sleeves and then packaged into bulk cartons for distribution. Paper sleeves can also be used for branding purposes.

Equipment Used In The Process

In the production of ice cream cones, each link relies on professional equipment to achieve efficient and standardized operations. The following is a detailed introduction to the core equipment and its functions in the cone processing process:

- 1. Mixer: used to mix flour, sugar, water, oil and other raw materials to form a uniform batter. Ensure that the batter is particle-free and has consistent fluidity.

- 2. Cone baking and rolling line: Accurately control the amount of batter injection to reduce waste. Multiple molds are baked simultaneously. Partition temperature control technology ensures consistent color of the cone.

- 3. Conveying and cooling finishing line: The conveyor belt cooperates with the cold air system to quickly cool down and shape. Sort the cones by size/shape and connect to the next process.