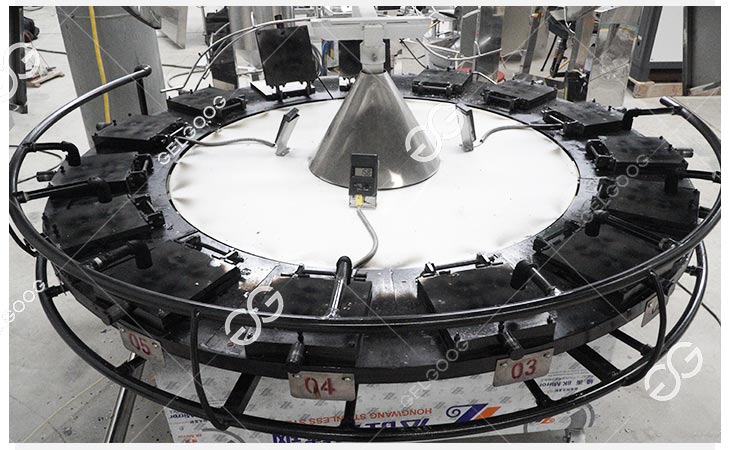

The ice cream sugar cone machine is a 12-mold machine that specializes in producing high-quality sugar cones. This machine is the first choice for companies that seek efficiency, versatility and reliability.

The machine is designed to meet both electric and gas heating methods. This also ensures that it can be used by food producers in different countries and regions.

Features of the Ice Cream Sugar Cone Machine

- Dual Power Options: The machine offers the flexibility of electric or gas power, making it suitable for various production environments and energy preferences.

- High Production Capacity: Capable of producing thousands of sugar cones per hour, this machine is ideal for businesses looking to scale their operations.

- User-Friendly Design: The features intuitive controls that simplify operation for users of all skill levels. Its ergonomic design ensures ease of use, streamlining the production process and boosting overall efficiency.

- High-grade materials ensure robustness and long-term reliability. The ice cream sugar cone making machine withstands continuous use, maintaining consistent performance and minimizing downtime.

- Hygienic and Easy to Clean: Food-contact components are designed for easy disassembly and thorough cleaning. This ensures compliance with hygiene standards and reduces contamination risks.

How to Operate the Ice Cream Sugar Cone Making Machine

- Prepare raw materials: Mix sugar, flour, eggs and other raw materials according to the formula, stir evenly to make sugar cone batter. Make sure the batter has a uniform texture and no particles.

- Preheating: Turn on the machine power and select the required heating mode (electric heating or gas heating). Preheat the machine to the set temperature (usually 180-200°C) according to production needs.

- Batter Injection: Pour the prepared batter into the hopper. The industrial ice cream sugar cone machine will automatically elevate the batter and dispense it onto the baking tray.

- Baking: The batter is baked into sugar cone sheets using heating and clamping devices. The typical baking time is 60 seconds, which can be adjusted based on the batter thickness and temperature.

- Rolling sugar cones: After the sugar cone sheets are mature, the mold opens automatically, and the operator needs to quickly remove the sheets from the baking tray and roll them into cones on the rolling machine.

The ice cream sugar cone machine is more than just a piece of equipment; it’s a comprehensive solution designed to elevate your business. Combining advanced technology with robust durability and user-friendly design, the machine offers unmatched performance for both small bakeries and large manufacturers.

Whether you aim to expand your product line or optimize your production process, the machine is a valuable investment that delivers consistent quality and efficiency. Get a quote contact email: [email protected], whatsapp: +8615515571373.

Technical Parameters

| Model | Capacity | Power | Biscuit Size | Biscuit Thickness | Dimension | Weight |

| GGDCD6 | 300PCS/H | 10KW | 7-20CM | 0.5-4MM | 140*140*125CM | 250KG |

| GGDCD9 | 400-600PCS/H | 14.5KW | 7-20CM | 0.5-4MM | 160*160*125CM | 270KG |

| GGDCD12 | 600-800PCS/H | 19KW | 7-20CM | 0.5-4MM | 170*170*125CM | 300KG |

| GGDCD15 | 800-1000PCS/H | 23KW | 7-20CM | 0.5-4MM | 180*180*125CM | 330KG |

| GGDCD18 | 1000-1200PCS/H | 28KW | 7-20CM | 0.5-4MM | 190*190*125CM | 360KG |

Get a Quote for Your Cone Machine

Let us know your requirements by filling out the form below. our team will get back to you with a tailored quote for the ice cream cone making machine that fits your business.

Reviews

There are no reviews yet.